Unlocking the Power of Engines: A Comprehensive Overview to Efficiency and Effectiveness

Understanding the complex technicians of engines is essential for both efficiency enthusiasts and day-to-day chauffeurs. By examining crucial metrics such as horse power and torque, one can appreciate exactly how adjusting techniques enhance effectiveness while addressing environmental worries. In addition, regular maintenance plays an essential duty in sustaining ideal efficiency with time. As the vehicle landscape changes in the direction of electrification and advanced technologies, the concern develops: just how can we effectively adapt to these changes while optimizing engine capacities? The answers may redefine our approach to engine performance and effectiveness in manner ins which are both informing and essential.

Comprehending Engine Essentials

What comprises the basic technicians of an engine? At its core, an engine is a machine designed to convert gas into mechanical power with a series of regulated explosions or combustion processes.

The crankshaft then changes this linear motion right into rotational energy, which ultimately powers the vehicle. The camshaft manages the opening and closing of the valves, managing the intake of air and gas and the expulsion of exhaust gases. Furthermore, the engine depends on a very carefully calibrated fuel-air blend, ignition system, and cooling system to make certain ideal performance and effectiveness.

Comprehending engine essentials likewise entails acknowledging the value of engine cycles, such as the four-stroke cycle, that includes intake, exhaust, compression, and power strokes. Each stage is critical in making sure the engine functions efficiently and effectively. Proficiency of these basic auto mechanics lays the groundwork for checking out more complicated engine characteristics and performance metrics, necessary for optimizing both power outcome and performance.

Key Efficiency Metrics

Trick performance metrics are vital for evaluating an engine's effectiveness and power outcome, giving important insights for both suppliers and customers. These metrics work as benchmarks for engine performance, enabling for notified choices in production, layout, and buying.

Among the main metrics is horse power, which evaluates the engine's capability to do work over time. Torque, determined in pound-feet, is an additional important statistics that shows the engine's rotational force, directly affecting velocity and towing capacity. Gas effectiveness, commonly gauged in miles per gallon (MPG) or litres per 100 kilometers (L/100km), analyzes exactly how successfully the engine converts fuel into activity, influencing ecological factors to consider and functional costs.

In addition, thermal effectiveness steps exactly how well an engine converts gas power right into helpful work, exposing insights into power losses largely via warmth. Emission degrees, consisting of carbon dioxide and NOx, are likewise vital, showing the engine's environmental effect and conformity with regulatory standards.

Tuning Strategies for Performance

Tuning strategies play a significant role in improving engine effectiveness by enhancing efficiency metrics recognized in earlier conversations (ford fiesta engine). Numerous approaches exist to fine-tune an engine, each adding to boosted gas economic climate and lowered exhausts

One reliable strategy is readjusting the air-fuel proportion, making certain the engine runs within the optimum burning regimen. A leaner combination can boost gas effectiveness, however it should be balanced to stop misfires or engine knock. a knockout post Additionally, reprogramming the engine administration system can alter parameters such as ignition timing, which even more improves efficiency while maintaining power output.

An additional crucial technique involves modifying the consumption and exhaust systems. Upgrading to high-performance air filters and exhaust headers can minimize back pressure, promoting far better air flow. This allows the engine to take a breath more freely, leading to enhanced burning performance.

In addition, the execution of sophisticated tuning devices, like dyno testing, gives specific information that makes it possible for targeted modifications. Routinely keeping an eye on these performance metrics ensures that adjusting efforts produce the preferred performance results. Jointly, these methods not just reinforce engine efficiency however additionally add to long-term sustainability in engine procedures.

Maintenance for Ideal Efficiency

Routine check my site engine upkeep is vital for attaining optimal efficiency and longevity. A well-kept engine not only operates successfully but additionally minimizes the threat of costly repair services and breakdowns. Secret parts requiring routine focus include oil, filters, belts, and ignition system.

Changing the engine oil at suggested periods is vital, as oil lubes moving components and stops getting too hot. Likewise, replacing oil and air filters makes certain that contaminants do not harm engine function. Neglecting these elements can bring about reduced efficiency and possible engine damages.

Additionally, checking and replacing used belts and hose pipes is essential to stop sudden failures. Timing belts, in certain, should be replaced according to the producer's timetable to avoid devastating engine damage.

Spark plugs must also be inspected and replaced as needed, considering that they play a crucial role in ignition and fuel performance.

Future Fads in Engine Technology

Embracing developments in innovation, the future of engine style is poised to transform performance and efficiency throughout numerous applications. Among one of the most considerable patterns is the shift toward electrification. Crossbreed and totally electrical powertrains are ending up being progressively mainstream, offering reduced exhausts and improved fuel efficiency. This transition is not just a need yet a pattern driven by governing stress and consumer demand for lasting services.

In addition, advancements in products scientific research are bring about lighter, more powerful elements that enhance engine efficiency while minimizing power usage. Advanced manufacturing strategies, such as 3D printing, permit the creation of intricate geometries that enhance airflow and thermal monitoring, hence optimizing burning processes.

Furthermore, the integration of expert system and equipment knowing is set to transform engine diagnostics and performance adjusting. These modern technologies read more can analyze substantial amounts of information in genuine time, enabling predictive maintenance and tailored performance improvements.

Verdict

In final thought, opening the power of engines calls for an extensive understanding of their mechanics and efficiency metrics. Executing reliable tuning techniques and adhering to regular maintenance techniques substantially boost engine capacities. As the vehicle landscape advances, accepting future fads in technology, including electrification and progressed manufacturing, will certainly be essential for enhancing efficiency and efficiency. This thorough strategy not only advantages fanatics yet additionally adds to sustainable solutions in the world of auto engineering.

In addition, the engine depends on a very carefully calibrated fuel-air mixture, ignition system, and cooling down system to guarantee optimal efficiency and effectiveness.

Understanding engine essentials likewise involves identifying the importance of engine cycles, such as the four-stroke cycle, which includes consumption, compression, power, and exhaust strokes. Proficiency of these fundamental technicians lays the groundwork for discovering much more intricate engine dynamics and efficiency metrics, crucial for maximizing both power output and performance.

Welcoming improvements in modern technology, the future of engine layout is poised to change efficiency and effectiveness throughout different applications.

Danny Tamberelli Then & Now!

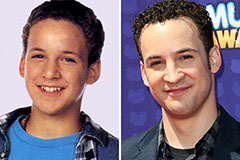

Danny Tamberelli Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Shane West Then & Now!

Shane West Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now!